Search

Perkins 4000 Series fuels India's power growth

A record number of engines were sold in India in FY2022-23.

Sany opens its state-of-the-art facility in Pune

Strengthens presence in Maharashtra

We are launching new ‘Made for India’ tyres

Rajiv Poddar, Joint Managing Director, Balkrishna Industries, speaks on the key products on display during bauma CONEXPO.

Perkins celebrates production of 10,000th 4000 Series engine

Perkins’ Aurangabad facility has achieved a major milestone after its 10,000th 4000 Series engine rolled off the production line.

Tata Motors plans to invest Rs 15k cr in EV market

Tata Motors, a leading global automobile manufacturer, is planning to invest Rs 15,000 crore in the electric vehicle (EV) segment over the next five years.

Goodyear India revenue up 18%

Third quarter profit after tax of Rs 19 crore, down from third quarter last year of 49 crore on higher commodity prices

Infra push to drive demand for diesel engines

Factors such as demand for reliable electricity, which is growing across the world on account of industrial expansion and development of commercial infrastructure are driving the diesel power engine market.

Volvo CE speeding up infra developments in India

Volvo Construction Equipment (Volvo CE) is supporting infrastructure growth across India with its range of construction equipment.

Premium Transmission opens product development centre in Kolkata

Premium Transmission, one of the leading players in industrial gearboxes, geared motors and fluid coupling market of India, is strengthening its footprint in eastern part of the country by opening new product development centre in Kolkata.

CASE Construction Equipment opens new dealership in Bihar

CASE Construction has strengthened its distribution network in Bihar with the opening of a new dealership facility, Patliputra Earthmover Pvt Ltd, near Didarganj in Patna. Spread across 10,000 sq ft, this facility is the largest CASE India footprint in Bihar.

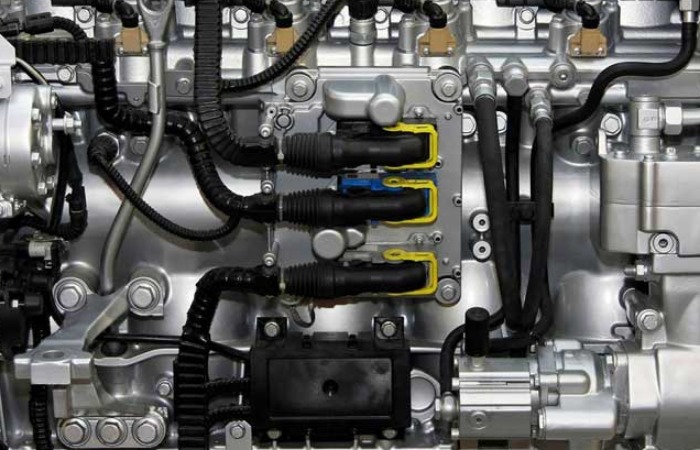

Perkins launches electronic diesel engine

Perkins announced the launch of the first electronically controlled, highly sophisticated engine, utilising the technology specifically designed for the 4000 Series range.

Productive Paver

India is building roads at an unprecedented rate. Since 2014, the country has laid 28,000 km of highways at a cost of nearly Rs 3 trillion. Over the next decade, the country is expected to add 85,000 km more roads under the Bharatmala and Sagarmala infrastructure initiatives.

Perkins launches electronic diesel engine

Perkins announced the launch of the first electronically controlled, highly sophisticated engine, utilising the technology specifically designed for the 4000 Series range.

Trimble unveils pan-India training program

Trimble has unveiled its pan-India training program to train the next-generation of engineering and construction industry professionals. The company also announced the opening of its latest Tekla Authorized Training Center (ATC) in Vijayawada, taking the number of ATCs to 17 across India.

JNPT to develop two dry ports

According to reports, Jawaharlal Nehru Port Trust (JNPT) is planning to develop two dry ports at Jalna and Wardha over the next 18 months.

Shell Lubricants hosts Energy Efficiency Summit 2017

Shell Lubricants and the Confederation of Indian Industry (CII) under the aegis of the Energy Efficiency Council along with Godrej GBC, organised the 16th edition of ?Energy Efficiency Summit?, International Conference and Exposition.

Safexpress to set up six logistics parks

The leading supply chain and logistics services provider Safexpress has lined up a plan to set up six logistics parks across the country at an investment of Rs 300-crore.

Gearing up for the next level

Says Mathur, ?It is the government agencies who are asking for the implementation of Euro-V and VI (norms).

Our tower cranes are 100 per cent locally sourced and manufactured

We mainly focus on brand building. This is an opportunity for our customers to come and meet us and see the products on display. This year, we launched a crane at the event in two variations: 6 tonne and 9 tonne. It is completely localised, positioning us well in the market.

Perkins Engine Facility Inaugurated

The Chief Minister of Maharashtra, Devendra Fadnavis, has officially inaugurated Perkins world-class engine manufacturing facility in Aurangabad.

BC India buzzing

India?s construction equipment market is currently in the vertical portion of the U trajectory of growth. Many analysts predict a sustained growth in double digits for the next decade, to begin with. Obviously, the allied industry will be an equal partner in this growth story.

Maharashtra CM inaugurates Perkins? Aurangabad facility

The Chief Minister of Maharashtra, Devendra Fadnavis, has inaugurated Perkins? world-class engine manufacturing facility in Aurangabad.

The Tyre Game

The new plant at Bhuj is a result of BKT?s ambitious vision to become a global leader in off-highway tyres. If the off-highway tyre market was a chess game, BKT would be preparing to checkmate the same to claim its place as a global leader.

Perkins exhibits at Make in India Week

Perkins Engines Company Limited showcased its powerful 4000 Series engine range, manufactured at its new facility in Aurangabad, at the Make in India Week in Mumbai.

Empowering Customers with Organised Approach

Two decades ago, India opened its doors for multinational automobile companies allowing them to penetrate the market, modernise the Indian transportation picture and make it beneficial for the end-users.

We have 12 LiuGong loaders as on date

Shree Cement is primarily an Indian cement manufacturer, founded in Beawar in Ajmer district of Rajasthan in 1979. It is now one of the biggest cement makers in North India. It also produces and sells power under the name Shree Power (captive power plant) and Shree Mega Power (independent power plant).

Rising with a Holistic Approach

With a vision to become a global leader in off-highway tyre solutions, BKT has a three-fold strategy of expanding its reach. BKT (Balkrishna Industries Ltd), the off-highway tyre manufacturer which has been in the business for 27 years

Indian OEMs and Perkins leaders look ahead to 2015

Perkins Engines Company recently held its 6th Global Original Equipment Manufacturers (GOEM) Council in Delhi.

Perkins holds distributor meets

The new Global Sales and Marketing Director of Perkins, Bill Giunta has visited India, and interacted with the company?s Indian customers and generator set manufacturers.

Automotive forgings, splined shafts

Maso Automotives is a part of the Maso Group, a comprehensive solution provider to the various forged and machined components manufacturers. Catering to the requirements for a variety of industries ranging from automotives, farm equipments, earthmoving equipments and other engineering applications, Maso Automotives specialises in forged solutions for press, upset and hollow shafts through the radial forging technology.

Centre to sanction Rs 4,130 cr to Bihar for rural roads

The Union Rural Development Ministry has approved Rs 4,130 crore for construction of 5,700 km of rural roads in Bihar. The amount okayed by the centre is said to be the highest allotment for the State in the past 12 years. The decision to allot the amount under Prime Minister Gramin Sadak Yojna (PMGSY) in the current financial year was taken by the ministry in July, Union Minister Jairam Ramesh said in Patna.

Caterpillar and its dealer TIPL expand Rajasthan footprint

With the economy showing signs of improvement and demand for equipment in the infrastructure sector, Caterpillar and its Indian dealer network is aggressively expanding its footprint in Rajasthan in a bid to further bolster its sales and service network through TIPL,

Nashik's civic body to take up road works on its own

The Nashik Municipal Corporation (NMC) has decided to take up the work on the first ring road under its jurisdiction. The civic body has decided to the start the process of inviting tenders on its own and the actual work is expected to begin after the monsoon. The project will be executed under the deferred payment scheme due to paucity of funds.

Caterpillar sees India as export hub

Caterpillar is charting plans to serve other markets from India. The company has said that its Indian operations have become a key part of its global production network now,

Greaves Cotton rolls out 3 millionth light diesel engine

Greaves Cotton achieved a major milestone last month, with the roll-out of the 3 millionth light diesel engine. The company?s MD and CEO, Sunil Pahilajani, rolled out the engine at the Aurangabad facility.

We will launch CRDI technology-enabled engines for both automotive and nonautomotive applications.

With stateoftheart R&D centres in Italy, the US and India, we strive to give the very best in to the market in India and abroad. Our R&D is continuously working on development of compact, lightweight and fuel efficient engines,? says Sudipto Mukherjee, General Manager Marketing, Lombardini India. Excerpts from the interview. 0 - -

20041 14 102 2011-11-01 00:00:00.000 Behram Ardeshir An Engineering Marvel The first twin cylinder CRDI diesel engine launched in 2010, is an engineering marvel as it is compact, fuel efficient, powerful and is a flexi fuel engine that can run on diesel, CNG or LPG, writes Behram Ardeshir.

Cooper Corporation has a ninety year old pedigree. They have always relied on technology and innovation. In 1922, Cooper made India's first diesel engine. In 2010, they produced India's first twin cylinder, CRDI, Euro IV compliant diesel engine.Cooper Corporation, a leading manu?facturer of engine components like liners, crankshafts, blocks, heads etc for decades, have now decided to set up a state of the art engine manufacturing facility. This is the first Greenfield engine manufacturing facility, other than a small scale operation, to be set up in decades anywhere in the world.

Ricardo of UK was assigned the task of designing the family of engines. The first engine is India's first twin cylinder CRDI diesel engine. This engine was launched in 2010 and is an engineering marvel as it is compact, fuel-efficient, powerful and is a flexi fuel engine that can run on diesel, CNG or LPG.

Farrokh Cooper, Chairman of Cooper Corporation was very clear at the outset. He wanted an engine that incorporated the latest international technology and one that was protected for future legislation as well. Thus Ricardo designed an engine that was Euro IV compliant and Euro V-protected. It was compact and fuel-efficient but Cooper wasn't ready to stop there. He wanted an engine that would work in both vehicular and off-road applications. Going a step further, he wanted the same engine to run on both diesel and gas! Cost of development was not a major factor. The result was a world's first, a twin cylinder CRDI engine that ran on diesel and gas, and was useable on-road and off-road. To top that, it met with all international legislation both present and future, it was compact and more efficient than most of its competition! Whilst most of the competition in India was counting their pennies and spending just what was needed to keep abreast of changing legislation, Cooper Corporation went the whole hog and produced a veritable engineering marvel. Now this engine has set a benchmark for the others to follow.

Once the engine was tested and validated, the engine plant was also ready to be commissioned. The detailed engineering and construction was carried out by Precision Automation and Robotics India of Pune. The team was led by

Dr Ranjit Date, Managing Director and Govind Oza was leading several teams connected with equipment design, layouts, detailed machinery and equipment design, material handling systems, electronic systems etc.

The brief given to them was four-fold:

a)The manufacturing line should be world-class, elegant with best use of technology to ensure satisfactory integration of the materials, design and components.

b)The emphasis would be on the state-of-the-art loading and unloading devices, clamping forces and special machines to ensure the wholesomeness and integration of the Ricardo design with the best engine components and aggregates made by Cooper and their vendors.

c)Cleanliness and a high level of protection from air laden contamination using modern air filtration systems in the ventilation provided in specific areas of assembly.

d)A common rail diesel injection that is a unique and priceless device for successful electronic engine management. This calls for surgical cleanliness in the storage, assembly and handling of the fuel injection system. For this purpose a high purity enclosure within the highly sanitised assembly hall has been designed and implemented.

This production line combines ergonomics and highly productive manual dexterity to augment the various powered mechanical systems for lifting, moving, clamping and measuring. This production line uses several IPV's (Inline Process Verification System) to make sure that the anufacturing process is carried out as per the Ricardo engineering specifications which are enshrined in the Ricardo engine build manual. At every stage after the manufacturing operations an automatic device is used for checking the integrity in assembly.

This production line is standard in that it has a conventional chain conveyor which is carrying on it the trolleys which are required for each engine. All the components of this engine are stored in kitting trolleys switched adjusted to the main assembly line trolley and have within easy reach the components and checking devices used for the assembly. The DC nut runners and other power tools are proved down from over head pneumatic and electric lines within easy reach they provide the necessary power carefully graduated as per the Ricardo tightening specifications.

The production capacity is 24,000 engines per annum and can easily be doubled to 48,000 when the market demand increases. There is further scope for increasing by robotizing selected assembly operations as and when needed. This flexibility has been built in to the system.

The present production line manufactures two cylinder normally aspirated engines and turbocharged engines for industrial automotive and other applications. The same line produces both normally aspirated and the turbocharged engines.

The exclusive requirements of the turbocharged engine as special piston assemblies, turbochargers and such components are stored and made available at specific locations before the engine goes to receive the exclusive fuel injection equipment for such applications. This equipment fitted in the Delphi room for fuel injection equipment assembly and fitment.

The manufacturing operations are not labour intensive in fact they are not even skill intensive. The requirement of manual dexterity is in fact not necessary in the operation of this production system but the workmen concern have to be thinking creative and able to use modern machines and devices to ensure perfection and integrity in assembly and quality.

That the production line is not labour intensive is borne out by the fact that at full capacity not more than eight workmen will be needed for the manufacturing of these engines. The next engine to be produced by Cooper will be their topline six cylinder diesel engine producing 180 to 308 BHP. This engine is currently undergoing endurance testing and should be launched in the near future. This will be followed by the four-cylinder diesel engine producing 121 to 208 BHP.Both engines will continue in the tradition of the twin cylinder by being compact, fuel efficient and low on emissions.

Today, the twin cylinder engine is being incorporated in Cooper Corporation's own range of gensets and talks are on with some major four wheel manufacturers to use this engine in their new range of vehicles. Cooper also has their own small commercial vehicle rolling out next year fitted with this engine. Again this vehicle will feature an ergonomic design and features hitherto available only in passenger cars.

Cooper believes in the future. As an effective insulation from the vagaries of economic cycles, the company has consistently ploughed back its profits into operations and has invested in the latest state of the art technology. It has taken several measures to promote conservation of resources like installation of voltage stabilisers, automatic power correction panels, energy efficient light fittings and 15 windmills. The company has always been technology-driven having won numerous awards and recognition of services by many multinational customers from around the world. Furthermore, the company is ISO 9001:2000 and already certified by TS 16949.

Engines of growth

Studies show that at present as per 2010 figures, diesel engines in India emit a total of 357,959 tonne of pollution. If we were to use diesel engines with lower emissions, then this figure would be reduced to 116,325 tonne. Couple this with the fact that there are over 400,000 diesel powered vehicles being produced every year and 250,000 diesel powered gensets

Siemens delivers 100th GIS

The Power Transmission Division, part of the Energy Sector, celebrated handing over of 100th Bay of Gas Insulated Switchgear (GIS) from its state-of-the-art factory at Aurangabad, Maha?rashtra. The GIS was handed over to Gujarat Energy Trans?mission Corporation (GETCO)

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com